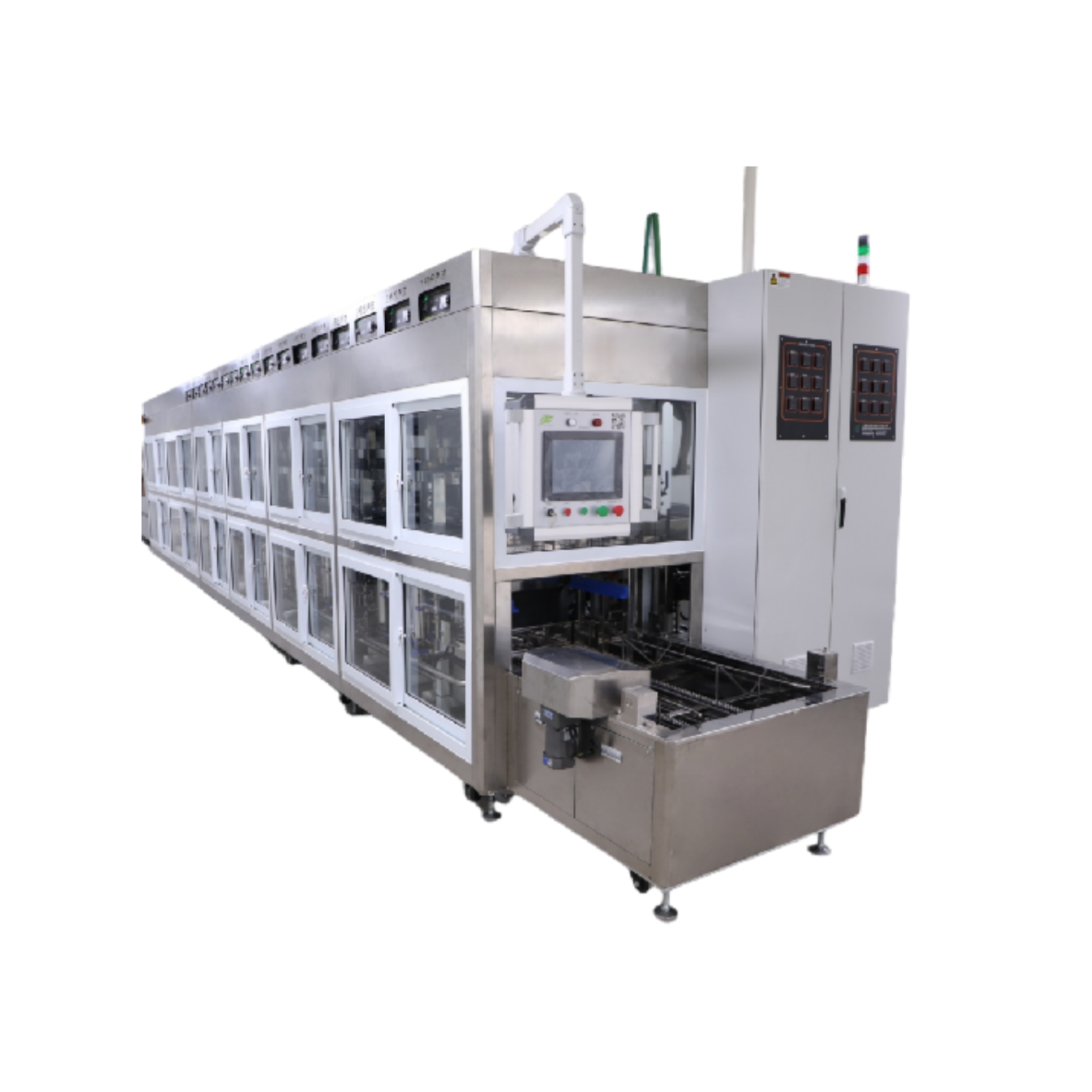

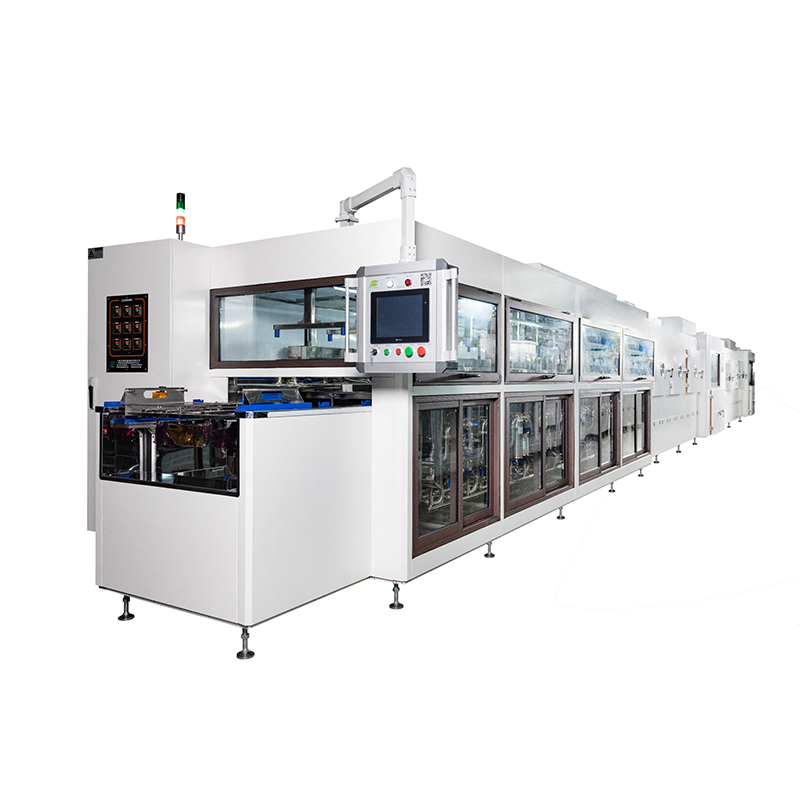

Sports protective goggles cleaning and hardening machine

I. Core Functions and Process Flow of Sports Protective Goggles Cleaning and Hardening Machine

The sports protective goggles cleaning and hardening machine is an intelligent cleaning device that integrates the entire process of precision cleaning, surface coating, curing and drying. It is suitable for optical PC lenses, goggles, helmets and other products.

Typical process flow

Feeding and pretreatment: The automatic feeding system sends the lenses into the cleaning tank.

Ultrasonic cleaning: High-frequency ultrasonic waves (such as 40kHz or 68kHz) combined with eco-friendly cleaning agents (deionized water, ethanol, etc.) are used to remove surface oil stains, fingerprints and particulate contaminants.

Rinsing and dehydration: After multi-stage pure water rinsing, water residue is reduced through slow pulling dehydration or hot air drying.

Hardening treatment: By using chemical coating or spraying technology, an anti-fog and anti-scratch layer is formed on the surface of the lens to enhance durability.

Drying and discharging: The final drying ensures the curing of the coating, and the automated discharging system enhances efficiency.

II. Technical Features and Key Parameters

Core technology

Ultrasonic cleaning system: High-frequency ultrasonic waves (28KHz-40kHz-68kHz) combined with multi-tank design (cleaning, rinsing, and pure water tanks) ensure thorough cleaning without any dead corners.

Hardening coating process: anti-fog (such as IPA steam bath washing) or chemical hardening (such as silane coating), to increase the surface hardness of the lens to over 9H.

Environmental protection design: Water-based cleaning agent circulation filtration system, reducing the discharge of chemical waste liquid by 58%.

Key parameters

Cleaning efficiency: 10-50 pieces per minute (depending on the degree of automation).

Temperature control: The cleaning solution is kept at a constant temperature of 25℃-60℃, and the drying temperature can reach 80℃-120℃.

Cleanliness standard: Complies with ISO 14644 Class 100 or below.

Optical industry

Cleaning and hardening of sports protective glasses and frames.

Consumer electronics

Anti-scratch coating processing for mobile phone panels and car rearview mirrors.

Medical Care and Scientific research

Maintenance and cleaning of laser equipment lenses and optical instruments.

III. Industry Development Trends

Automation and Intelligence

Integrate AI visual inspection to automatically identify contaminated areas and adjust cleaning parameters.

Green process upgrade

Promote chemical solvent-free cleaning (such as supercritical CO₂ technology).

High-precision requirements

Suitable for cleaning and hardening of micro-nano optical components (such as AR/VR lenses).

IV. Product Advantages

The equipment features advanced technology and exquisite workmanship

1. The normal service life exceeds 15 years, with a qualification rate of over 95%, reaching the technical level of imported equipment and offering a higher cost performance.

2. The equipment has a high degree of cleanliness, and the pipelines are welded with special techniques.

3. The mechanical hand can perform high-speed and precise action operations, replacing the uncertainty and inefficiency of manual operations, and realizing multiple tasks such as processing, assembly, handling and sorting.

4.Our company has a technical and after-sales service team with nearly 20 years of experience, providing customers with professional solutions from design and production to after-sales service.

V. Selection and Maintenance Suggestions

Key points for selection

Choose a multi-slot or single-slot model based on the lens size and production capacity.

Give priority to equipment equipped with HEPA filtration and temperature control systems to ensure cleanliness and process stability.

Maintenance and care

Replace the filter and cleaning agent regularly (every 1-2 years).

Calibrate the power of the ultrasonic generator to prevent damage to the lenses.

Process flow

Feeding - chemical cleaning - RO water rinsing - DI water rinsing - water cutting - drying - hardening - pre-curing

Product Specification

| Product Model | SFSY-09-2 |

| Cleaning Capacity | 2排 |

Machine Size(mm)L*W*H | 26600mm*2140mm*2100mm |

Voltage and Frequency(V/HZ) | 380V/50HZ |

| Power | 160KW |

| Water Consumption | 1250L |

| Machine Weight | 11000KG |

This equipment can be designed, developed and manufactured according to different product specifications and production capacities.

Leave A Comment