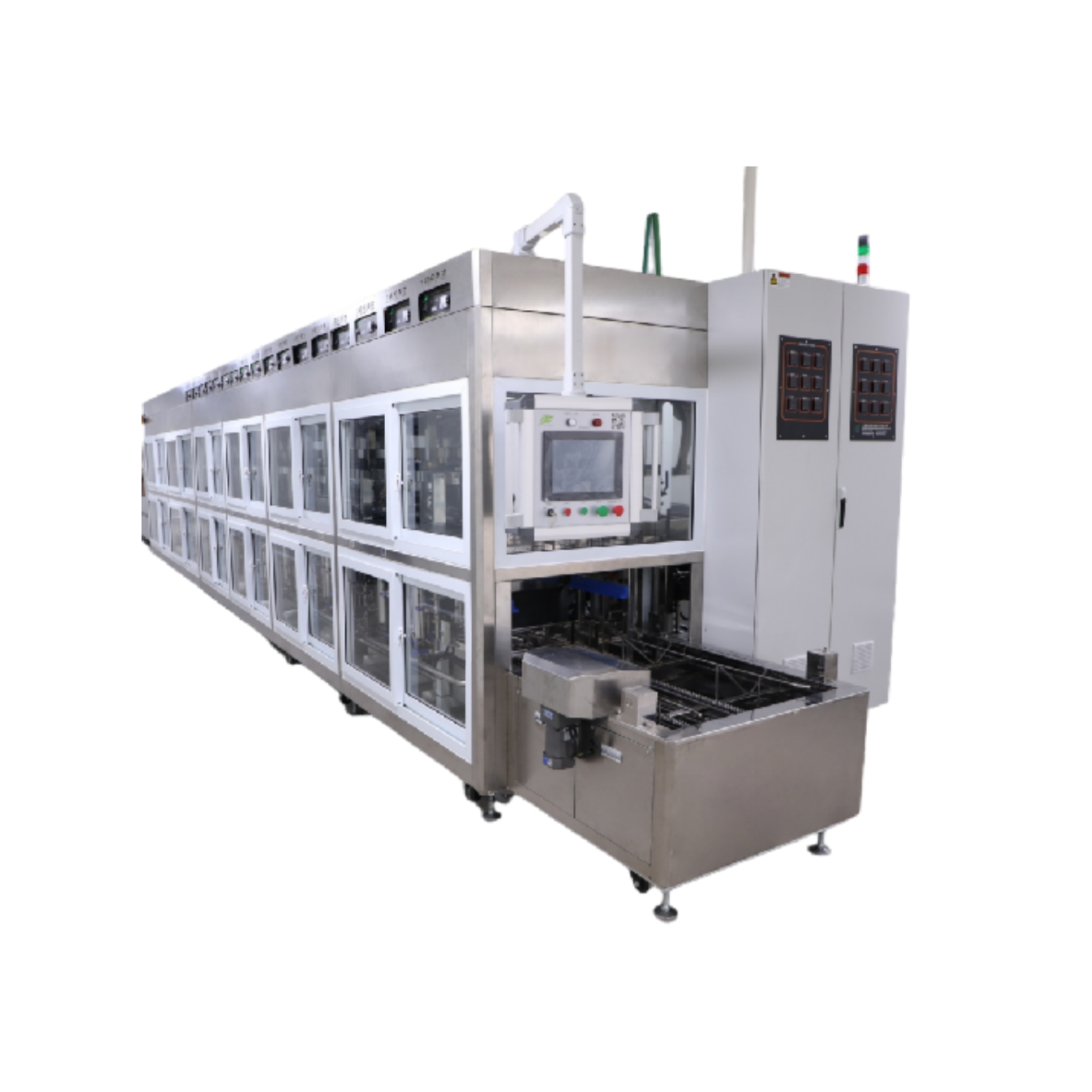

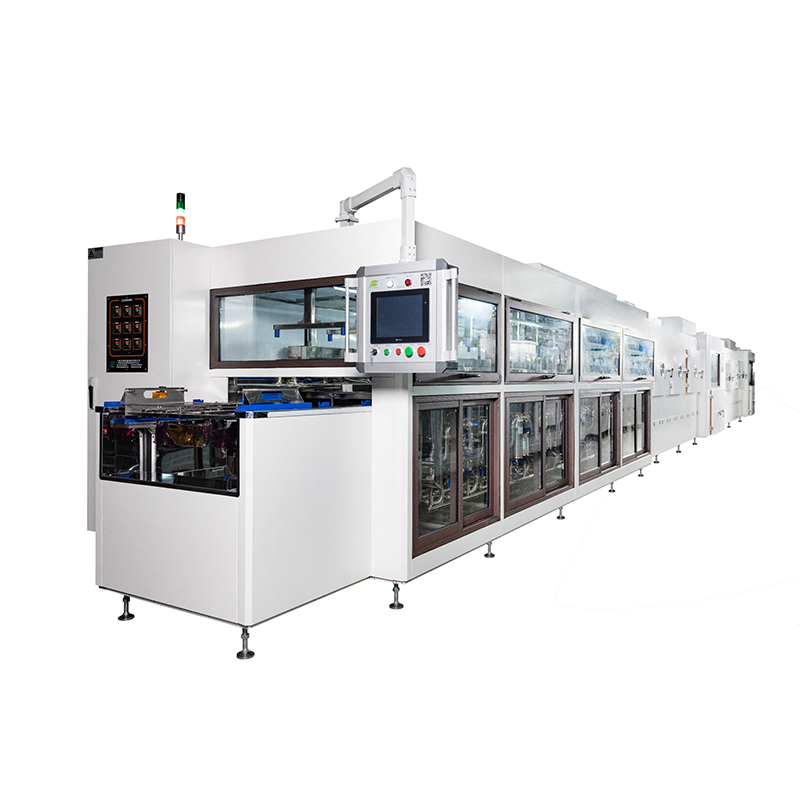

Testing oven

1. Product Introduction

The test furnace is suitable for drying and aging optical lenses, electronic products, components, parts and their materials in a high-temperature and constant-temperature environment, as well as for heating workpieces and general dehydration and drying.

By simulating different high-temperature environments, the optical performance and physical structure changes of optical lenses under high-temperature conditions are precisely detected, providing reliable data support for the quality assessment, material screening and process optimization of lenses. This equipment adopts advanced temperature control technology and an intelligent control system. It is easy to operate and provides accurate test results. It is widely used in the production, research and development, and quality inspection of optical lenses.

2. Core performance

Precise temperature control system: It adopts imported high-precision temperature sensors and advanced PID temperature control algorithm. The temperature control accuracy can reach ±0.5℃, and the temperature control range covers room temperature to 800℃, which can meet the testing temperature requirements of different types of optical lenses. The temperature distribution inside the furnace is uniform, with a temperature difference of less than ±3℃, ensuring that all parts of the test samples are heated evenly and enhancing the reliability of the test results.

Stable heating and cooling rates: The heating rate can be freely adjusted within the range of 1-20℃/min. The cooling rate, through an optimized cooling system design, can reach up to 15℃/min at the fastest, which can simulate the temperature change curve of the lens during actual use and truly reflect the thermal response characteristics of the lens.

Comprehensive testing function: Supports multiple testing modes, including constant temperature testing, heating and cooling cycle testing, step heating testing, etc. It can monitor and record in real time the temperature, time and optical parameter changes of the lens during the testing process (requiring corresponding optical detection accessories), automatically generate test reports, and facilitate users to conduct data analysis and traceability.

Safe and reliable design: Equipped with a complete safety protection system, including over-temperature alarm, overcurrent protection, power-off protection upon door opening, etc. The furnace body is made of high-quality high-temperature resistant materials, and the shell is made of cold-rolled steel plate with plastic spraying treatment. It has excellent heat insulation performance and corrosion resistance, ensuring the safe and stable operation of the equipment and extending its service life.

3. Product Specification

| Product Model | SFG-T | SFG-L | |

| Machine Size(mm)L*W*H | 625mm*450mm*500mm | 490mm*500mm*625mm | |

Power | 500W-1050W | 750W-1050W | |

Voltage and frequency(V/HZ) | 220V/50HZ | 220V/50HZ | |

| Temperature difference | 0.1℃/±0.5℃ | 0.1℃/±0.5℃ | |

| Machine Weight | 20KG | 75KG |

Leave A Comment